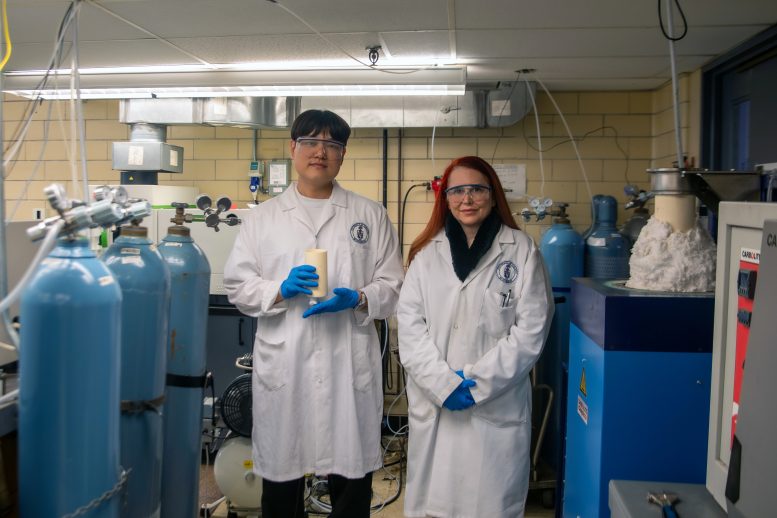

Engineering professor Gisele Azimi and her research team at the University of Toronto have developed a novel electrochemical method to extract contaminants like copper from steel scrap.

Researchers at the University of Toronto’s engineering department have developed a novel steel recycling technique that could help decarbonize various manufacturing sectors and promote a circular steel economy. The approach is detailed in a recent study published in the scientific journal Resources, Conservation & Recycling, and was co-authored by Jaesuk (Jay) Paeng, William Judge, and Professor Gisele Azimi.

It introduces an innovative oxysulfide electrolyte for electrorefining, an alternative way of removing copper and carbon impurities from molten steel. The process also generates liquid iron and sulfur as by-products.

“Our study is the first reported instance of electrochemically removing copper from steel and reducing impurities to below alloy level,” says Azimi, who holds the Canada Research Chair in Urban Mining Innovations.

Challenges in Current Steel Production

Currently, only 25% of steel produced comes from recycled material. But the global demand for a greener steel is projected to grow over the next two decades as governments around the world endeavor to achieve net-zero emission goals.

Steel is created by reacting iron ore with coke — a prepared form of coal — as the source of carbon and blowing oxygen through the metal produced. Current standard processes generate nearly two tonnes of carbon dioxide per tonne of steel produced, making steel production one of the highest contributors to carbon emissions in the manufacturing sector.

Traditional steel recycling methods use an electric arc furnace to melt down scrap metal. Since it is difficult to physically separate copper material from scrap before melting, the element is also present in the recycled steel products.

“The main problem with secondary steel production is that the scrap being recycled may be contaminated with other elements, including copper,” says Azimi. “The concentration of copper adds up as you add more scrap metals to be recycled, and when it goes above 0.1 weight percentage (wt%) in the final steel product, it will be detrimental to the properties of steel.”

Advantages of the New Method

Copper cannot be removed from molten steel scrap using the traditional electric arc furnace steelmaking practice, so this limits the secondary steel market to producing lower-quality steel product, such as reinforcing bars used in the construction industry.

“Our method can expand the secondary steel market into different industries,” says Paeng. “It has the potential to be used to create higher-grade products such as galvanized cold rolled coil used in the automotive sector, or steel sheets for deep drawing, used in the transport sector.”

To remove copper from iron to below 0.1 wt%, the team had to first design an electrochemical cell that could withstand temperatures up to 1600 degrees Celsius.

Inside the cell, electricity flows between the negative electrode (cathode) and the positive electrode (anode) through a novel oxysulfide electrolyte designed from slag — a waste derived from steelmaking that often ends up in cement or landfills.

“We put our contaminated iron that has the copper impurity as the anode of the electrochemical cell,” says Azimi. “We then apply an electromotive force, which is the voltage, with a power supply and we force the copper to react with the electrolyte.”

“The electrolyte targets the removal of copper from the iron when we apply electricity to the cell,” adds Paeng.

“When we apply electricity on the one side of the cell, we force the copper to react with the electrolyte and come out from iron. At the other end of the cell, we simultaneously produce new iron.”

Azimi’s lab collaborated with Tenova Goodfellow Inc., a global supplier of advanced technologies, products, and services for metal and mining industries. Looking forward, the team wants to enable the electro-refining process to remove other contaminants from steel, including tin.

“Iron and steel are the most widely used metals in the industry, and I think the production rate is as high as 1.9 billion tonnes per year,” says Azimi. “Our method has great potential to offer the steelmaking industry a practical and easily implementable way to recycle steel to produce more of the demand for high-grade steel globally.”

Reference: “Electrorefining for copper tramp element removal from molten iron for green steelmaking” by Jaesuk Paeng, William D. Judge and Gisele Azimi, 22 April 2024, Resources, Conservation and Recycling.

DOI: 10.1016/j.resconrec.2024.107654

1 Comment

Basically you still need a ton of acid, and get a ton of nasty byproducts… so what’s eco-friendly in it is beyond me.